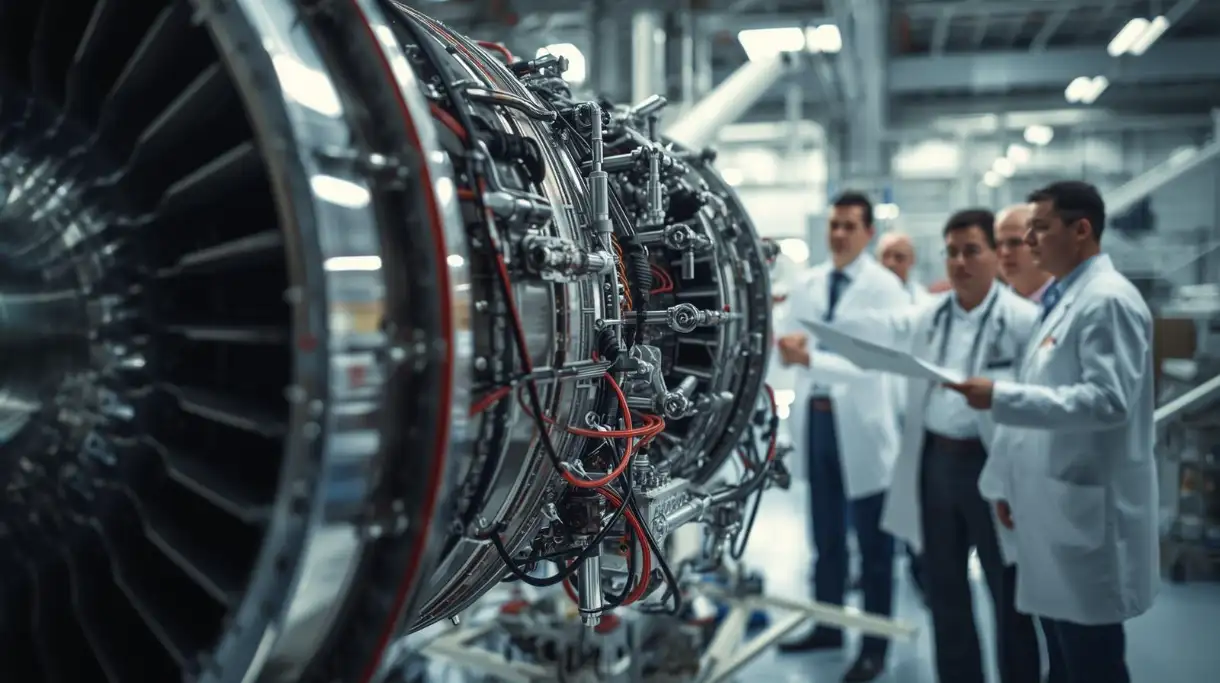

Engineers working on a jet engine

Scientists Use Synthetic Dust to Save Rolls-Royce Jet Engines

In Brief

- • Scientists developed a synthetic “desert dust” to realistically simulate harsh sandy conditions.

- • The artificial dust enables advanced testing of engine coatings and designs to extend engine life.

- • Early results show significantly longer engine service intervals, showing improved durability.

Jet engine builder Rolls-Royce has found a way to extend the lifespan of its jet engines, thanks to a new invention. Scientists at the University of Manchester created an artificial dust they have used to recreate desert conditions and build engines to withstand them.

According to a release on 16 December, the university’s Dust & Underground Science & Technology (DUST) group developed a synthetic test dust that accurately replicates the fine, talcum-powder-like particles commonly found in desert regions, responsible for accelerated wear on some aeroengine components.

The dust was used to simulate conditions in desert regions where jet engines easily harbor dust in order to build engines with higher resilience and ability to survive in such regions. The dust has become an important component of the company’s engine testing in Derby.

Solving the Problem of Sand in Rolls Royce

Rolls-Royce jet engines are used in different parts of the world including the Middle East where dust and sand is a major problem. Over the years, it has been observed that such sand is responsible for the fast wearing of jet engines used in those regions. In a bid to build more resistant ones, the scientists invented the artificial dust to simulate those deserts right in the lab.

The release says:

“Sand ingested during take-off and climb can penetrate the hottest parts of an engine, corrode components, and block coolant holes. While not a safety issue, the damage reduces efficiency, increases the maintenance burden, and shortens component life.”

Using the artificial sand, Rolls-Royce has managed to replicate harsh Middle Eastern conditions inside its Testbed 80 facility in Sinfin. Engineers then tested new coatings with better resistance against heat and corrosion, and redesigned coolant holes so they are less prone to blockage.

According to Pat Hilton, Rolls-Royce’s Test Facilities Manager, engine changes have been tested with the synthetic raw material and modified engines have returned to service, showing a 60% increase in time between overhauls, demonstrating more resilience against dust-induced engine damage.

Rolls-Royce’s Reputation in Jet Engine Maintenance

Rolls-Royce has a reputation in the maintenance of jet engines as seen by its role in research and servicing. Last month, the company in the Middle East entered a partnership with Emirates to maintain its Trent 900 A380 engines.

The research involving synthetic dust will help the company in making it better at maintaining Emirates engines especially against dust. Apparently, the discovery has added significantly to Rolls-Royce’s engine maintenance technology. Meanwhile, China is testing 3D-printed turbojet engines as a lightweight option to existing jet engines.

More Must-Reads:

How do you rate this article?

Subscribe to our YouTube channel for crypto market insights and educational videos.

Join our Socials

Briefly, clearly and without noise – get the most important crypto news and market insights first.

Most Read Today

Peter Schiff Warns of a U.S. Dollar Collapse Far Worse Than 2008

2Dubai Insurance Launches Crypto Wallet for Premium Payments & Claims

3XRP Whales Buy The Dip While Price Goes Nowhere

4Samsung crushes Apple with over 700 million more smartphones shipped in a decade

5Luxury Meets Hash Power: This $40K Watch Actually Mines Bitcoin

Latest

Most Read Today

MOST ENGAGING

Also read

Similar stories you might like.